- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Iimveliso

- Iibholiti kunye nezixhobo

- Izikrufu

- Iibholiti zeFlange

- Iibholiti zeT

- Allen screw

- Iibholiti zeHex

- Iibholiti zokuthwala

- Iibholithi U

- Ukucofa iScrew

- Izikrufu zoomatshini

- Self Drilling Screws

- I-Flange Nuts

- Hex Nut

- Tshixa nut

- Ukudibanisa Nuts

- Nut yaseNtwasahlobo

- Poleline Hardware

- Iwasha

- Iibholiti zeHex zoLwakhiwo

- Iibholiti zeHexalobular & Izikrufu

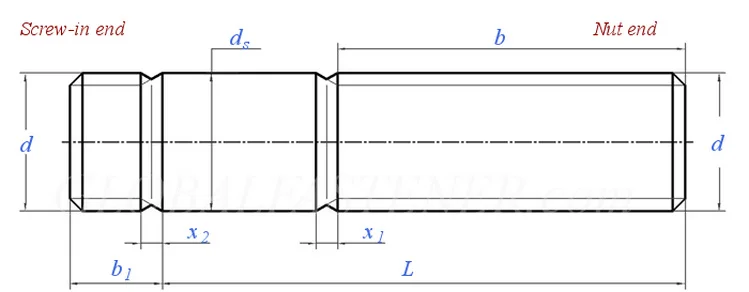

Izikhonkwane - Isiphelo sesinyithi ≈ 1 d

Ukuphucula iiprojekthi zakho nge-Studs nge-Metal End ≈1d DIN 938 - 2012. Yenziwe ngokuchaneka kunye nokuthotyelwa kwemigangatho yoshishino, ezi studs zibonelela ngokuthembeka okungenakulinganiswa kunye nokusebenza. Nokuba kukwakha, koomatshini, okanye kwimveliso, thembela kuzinzo nokomelela kwezi studi kwiimfuno zakho zokuqinisa.

Umzekelo:DIN 938

Thumela uMbuzo

Ingcaciso yeMveliso

Ukuchaneka okulungiselelweyo:I-Studs ene-Metal End ≈1d DIN 938 - 2012 zenziwe ngokucokisekileyo ukwenzela ukuba zifake izicelo ezichanekileyo, ziqinisekisa ukufakwa okukhuselekileyo nokuthembekileyo.

I-DIN 938 - 2012 Esemgangathweni:Ezi studs zibambelela ngokungqongqo kumgangatho weDIN 938 - 2012, ziqinisekisa ukuhambelana nokuthembeka kuzo zonke iisetingi ezahlukeneyo zemizi-mveliso.

Uzinzo olugqibeleleyo:Ngoyilo lokuphela kwentsimbi kunye nobude bokuzibandakanya malunga nokulingana ne-1d, ezi zikhonkwane zinika uzinzo olufanelekileyo kunye nomthamo wokuthwala umthwalo, uzenza zibe zilungele izicelo ezifuna ukuqina okuqinileyo.

| ①,Into: a) Intsimbi, iklasi yamandla: M3≤d≤M39: 5.6,8.8,10.9;d > M39: phantsi kwesivumelwano. Umgangatho we-DIN EN ISO 898-1 b)Olunye udidi lwamandla okanye izinto ngolungiselelo |